Our website is currently being updated. Please bear with us as some product information may not be readable while we update.

Fighting Fires and Viruses to help make a safer world

Dual action Fire and anti-microbial Paints

Our innovative paint designed to provide the new top standard Class B S1D0 fire rating as well as proven 91.5% Coronavirus reduction in 2 hours and 99.99% reduction in bacteria in 24hrs.

View Products

Fire Retardant Paint

Top quality paint designed to give great coverage and finish while providing the protection of new top standard Class B S1D0 fire rating.

View Products

Dual Action Fire and Anti-Microbial Varnishes

Our bestselling outstanding varnish, providing the new top standard Class B S1D0 fire rating as well as proven 91.5% Coronavirus reduction in 2 hours and 99.99% reduction in bacteria in 24hrs.

View Products

steel/Iron Coatings

Quick link to our bestselling steel and iron fire protection coatings

View Products

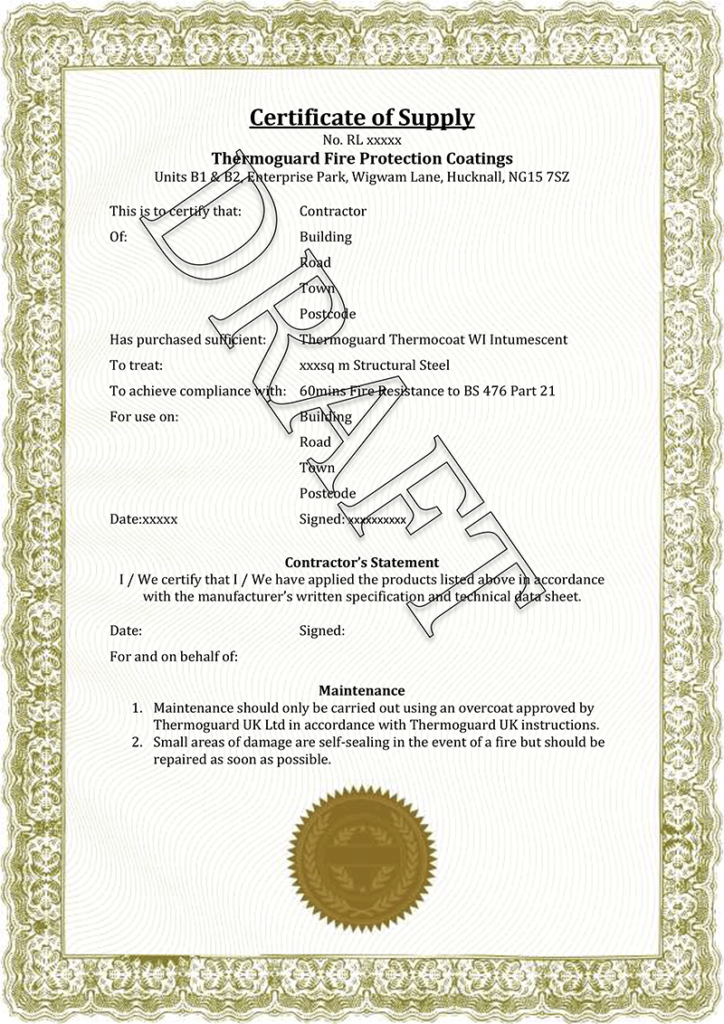

Certificate Request

Please follow link to our certificate request page to receive your certificate for your purchased products

Request Certificate

Asbestos Encapsulating Paint

Effectively prevents the release of asbestos and other fibres into the atmosphere by encapsulating them

View Products

Featured Product

Thermoguard SafeWalls Anti-Viral Smoke & Flame Retardant

Our easy application, great covering SafeWalls, saves you decorating time, needing comparatively less coats to cover, meets and exceeds in testing the new fire safety standard Class B S1D0, while also proving 91.5% coronavirus reduction in 2 hours, and 99.99% bacteria reduction in 24 hours, making it the go-to paint for decorators nationwide